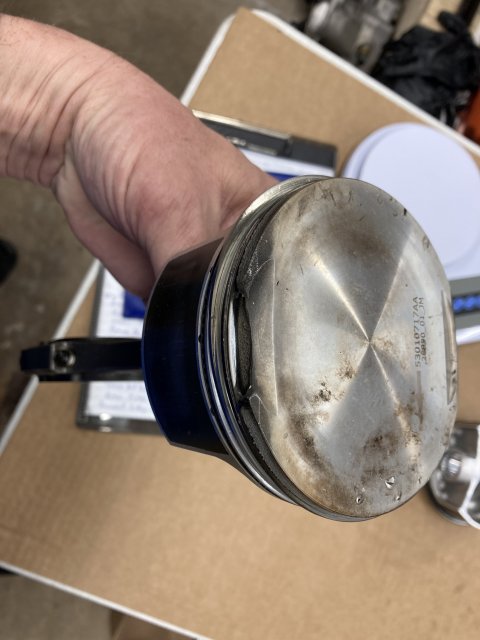

My number 7, typical failure, piston popped at thinnest point under a valve relief. A few theories, one is the corner cylinders run the leanest causing them to run hottest which leads to ring butting of the tightly gapped stock upper ring and pops the weakest part of the piston out exposing the ring to even more direct heat, the rings start to delaminate and leak more causing even more heat and expansion until the piston locks up at TDC on turnaround of the exhaust stroke and the bottom of the piston gets torn off and makes its last trip down the bore and out the bottom as on the next up stroke snaps the rod in half and makes a window to the world with the wrist pin like a shot gun slug.

View attachment 63612

View attachment 63613

View attachment 63614

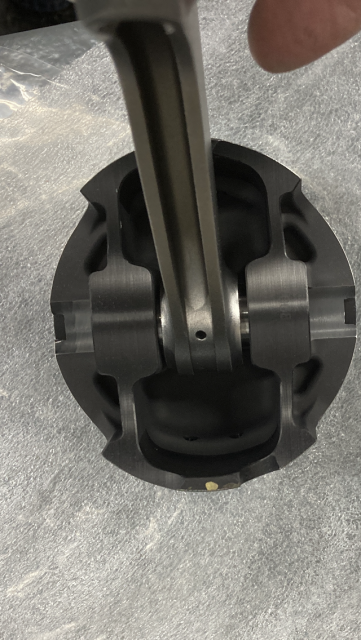

Replaced with these, .330” of meat between the fire storm and the ring, hard anodized top and ring lands and pin bores, PTFE coated bottoms and skirts. .250 wall H13 DLC pins with very close pin boss spacing on the piston keep crown flex to a minimum. Connected by a 4340 Manley H-Tuff rod on King Coated bearings. Top ring gap .026” verse stock .014-.018” which I think is the killer of these engines. Probably why a colder 180 Tstat helps and hot IAT’s and ambient temps doesn’t. Hoping this lasts a bit longer, someday see a bit of spray too possibly.

View attachment 63615

View attachment 63616

View attachment 63617

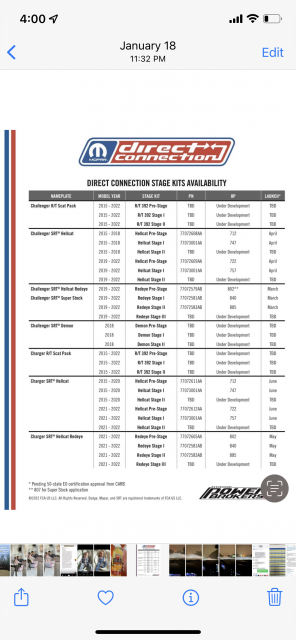

wont get the high octane option probably because it runs a single fuel pump and smaller injectors compared to the redeye dual fuel pumps and demon injectors. But stage 2 is in development

wont get the high octane option probably because it runs a single fuel pump and smaller injectors compared to the redeye dual fuel pumps and demon injectors. But stage 2 is in development